The history of the BeWooden products, Part 1: Where does the material come from?

Our products have a journey ahead of them before you use it. But it does not start in our workshop. BeWooden's story is born amidst nature, where we take all our materials from. However, our values and attitude to natural beauty are clear and we do not intend to cut down the forests for our unique accessories. Where do we get the material for our wooden accessories?

Waste for one is a treasure for another

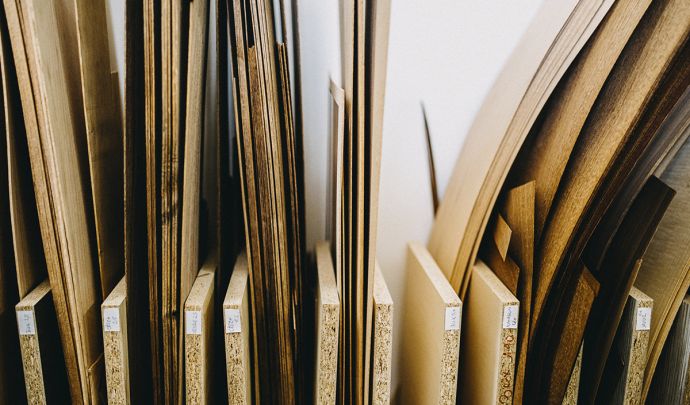

Throughout the Czech Republic there are many workshops where large pieces of material are used, these may be fabrics or wooden boards. So it happens that, for example, in the manufacture of large furniture a few small chips are just an unnecessary surplus. In something that, however, can mean waste for somebody, the other man can see great ideas. And that's the way things work for us at BeWooden - we try to use excess wood stocks, which are produced in the production of various pieces of furniture and are very pleased to be allowed to reuse the precious raw material with care. We put new life into pieces of wood that have been discarded or turned into chipboard.

Limited editions of special wood

Over the years, when we created unique accessories for you, there were times when we could produce from truly exceptional wood. For example, do you remember the unique vintage collection of bow ties from the barrels of the Spalek Winery? We still remember the beautifully natural colored wood that is bathed in the scent of fine wine.

Or do you remember that we teamed up with high school students in Africa to create another unique Made in Africa collection from the roof of an old building? You could then buy the supplement to help yourself with the project. And you still can! Look HERE.

Quality accessories can only be made of high quality leather

Although wood is still the essential for us, not everything can be made from it. At the same time, our vision is to cover craftmanship as much as possible, so choosing leather as another material is the obvious next step. We looked carefully for local suppliers because we are aware of the importance of the processing method for the quality of the leather. The properly tanned leather is more resistant to moisture and higher temperatures but also to bacteria.

Most of the leather products you buy today are chrome tanned. This is a modern method of tanning with chrome salts. It does not take as long and is less demanding than the vegetable tanning used to process our leather. This is the oldest tanning method. The agents are organic substances found in nature, mostly found in tree bark, leaves or roots of plants. Their extraction yields extracts that can be used for direct tanning. This can take up to several weeks. The leather is then heavy and strong, as made for the wise and diligent hands of our shoemaker Paul.

We support brands with the same vision

We do not compete with companies that also produce fair craftsmanship. On the contrary, we are always happy to see that we are not alone and that there are others who appreciate the magic of craftsmanship as well. That's why we work with the manufacturer Tonak for example, who has not changed anything in the proven traditional manufacturing process for more than 200 years.

What is the next step?

Everything starts with the right choice of materials. After that our product still has a long way to go until you hold it in your hands. In the next part our blogger Katka takes you to the workshop for a day. There you will be able to become part of our manufacturing process and you will have the opportunity to speak with those who create unique accessories every day.